Region:Global

Author(s):Dev

Product Code:KRAA3085

Pages:100

Published On:August 2025

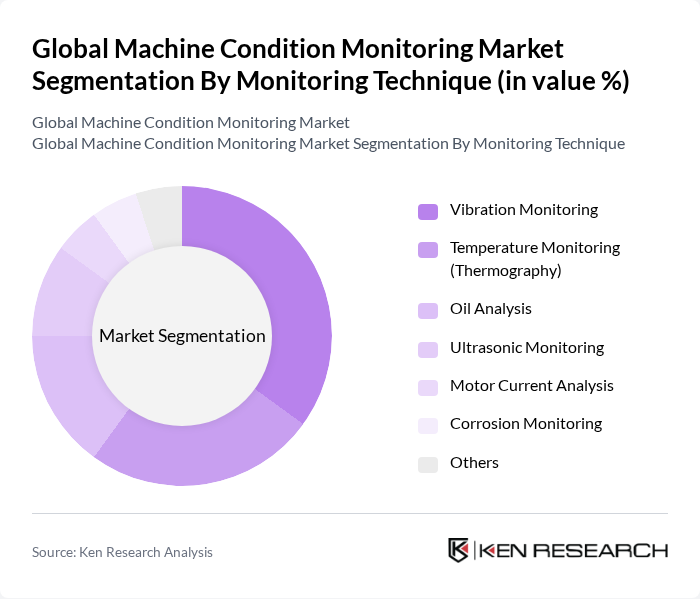

By Monitoring Technique:The monitoring techniques segment includes various methods used to assess the condition of machinery. The dominant sub-segment isVibration Monitoring, which is widely used due to its effectiveness in detecting mechanical faults early. Other techniques such asTemperature MonitoringandOil Analysisare also gaining traction as industries seek comprehensive solutions for predictive maintenance. The adoption of ultrasonic monitoring and motor current analysis is increasing, especially in sectors requiring early fault detection and energy efficiency. Wireless and cloud-based monitoring techniques are also emerging as important trends, enabling real-time diagnostics and remote asset management .

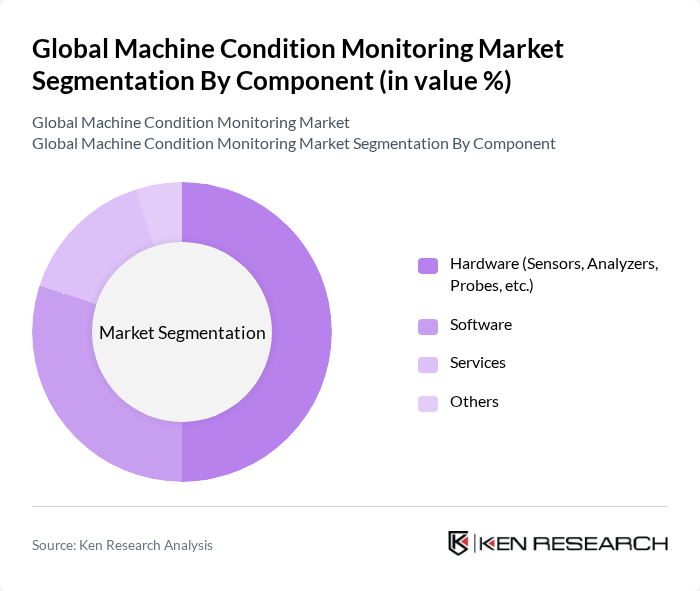

By Component:The components segment encompasses the various elements that make up machine condition monitoring systems.Hardware, including sensors, analyzers, and probes, is the leading sub-segment due to its essential role in data collection and real-time monitoring.Softwaresolutions are also critical, providing analytics and insights that enhance decision-making processes in maintenance. The demand for cloud-based and AI-driven software platforms is rising, supporting predictive analytics and remote diagnostics.Servicessuch as installation, integration, and maintenance support are expanding as end-users seek turnkey solutions and ongoing technical support .

The Global Machine Condition Monitoring Market is characterized by a dynamic mix of regional and international players. Leading participants such as SKF Group, Emerson Electric Co., Honeywell International Inc., Siemens AG, GE Vernova, Rockwell Automation, Inc., National Instruments Corporation, Yokogawa Electric Corporation, Bosch Rexroth AG, Fluke Corporation, Azima DLI, Parker Hannifin Corporation, Mitsubishi Electric Corporation, ABB Ltd., Bently Nevada (a Baker Hughes business), Schaeffler AG, ALS Limited, Meggitt PLC contribute to innovation, geographic expansion, and service delivery in this space.

The future of the machine condition monitoring market appears promising, driven by technological advancements and increasing industrial automation. As industries continue to embrace digital transformation, the integration of AI and machine learning into monitoring systems will enhance predictive capabilities. Furthermore, the shift towards sustainability will encourage companies to adopt energy-efficient monitoring solutions, aligning with global environmental goals. This evolution will likely lead to more customized solutions tailored to specific industry needs, fostering innovation and growth in the sector.

| Segment | Sub-Segments |

|---|---|

| By Monitoring Technique | Vibration Monitoring Temperature Monitoring (Thermography) Oil Analysis Ultrasonic Monitoring Motor Current Analysis Corrosion Monitoring Others |

| By Component | Hardware (Sensors, Analyzers, Probes, etc.) Software Services Others |

| By Deployment Mode | On-premises Cloud-based Hybrid |

| By Monitoring Process | Online Condition Monitoring Portable Condition Monitoring |

| By End-User Industry | Manufacturing Energy and Utilities Oil & Gas Chemicals Metals & Mining Automotive Aerospace & Defense Marine Food & Beverages Others |

| By Application | Predictive Maintenance Asset Management Quality Control Safety Monitoring Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Manufacturing Sector Condition Monitoring | 120 | Maintenance Managers, Production Supervisors |

| Energy Sector Monitoring Solutions | 90 | Operations Managers, Asset Managers |

| Transportation Fleet Monitoring | 60 | Fleet Managers, Logistics Coordinators |

| Healthcare Equipment Monitoring | 50 | Biomedical Engineers, Facility Managers |

| Mining and Heavy Equipment Monitoring | 70 | Site Managers, Equipment Maintenance Leads |

The Global Machine Condition Monitoring Market is valued at approximately USD 2.7 billion, driven by the increasing adoption of predictive maintenance strategies across various industries, including oil & gas, manufacturing, and aerospace.